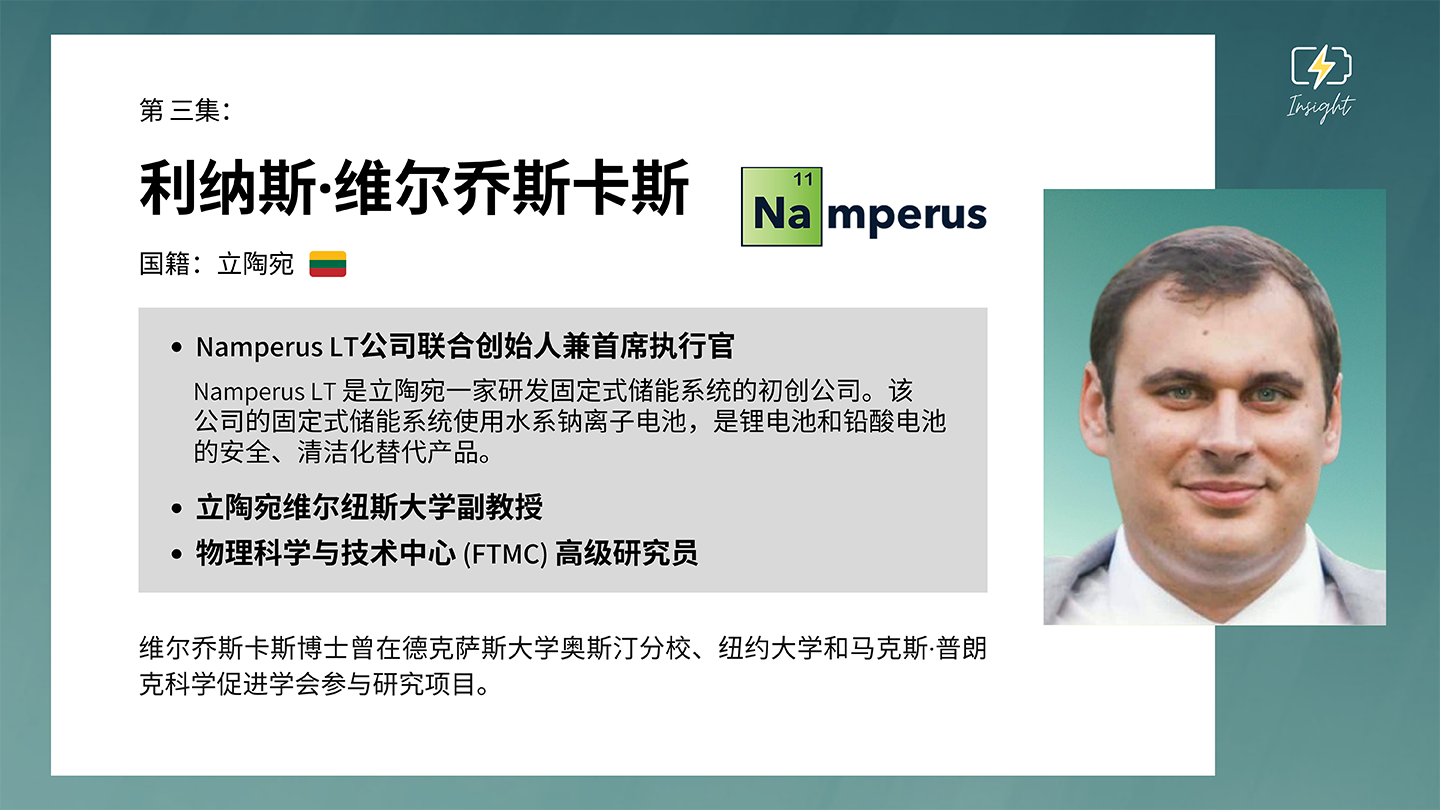

储能洞察访谈 第三集:利纳斯·维尔乔斯卡斯

近年来钠离子电池受到越来越多的关注,其中一个重要原因是与锂离子电池相比,钠离子电池的上游资源储量更丰富且成本更低。您认为锂离子电池与钠离子电池之间的主要区别有哪些?钠离子电池又具备哪些优势?

锂离子电池的主要优势是能量密度更高、制造工艺更成熟。区别于常见的锂离子电池,钠离子电池是一种使用钠离子作为电荷载体的可充电电池,与锂离子电池相比主要存在以下几方面的区别:首先是电池原材料储量上的区别,目前钠储量大约是锂的1000多倍。其次是阴极材料中钴的使用。钴是一种相对稀有、昂贵的资源,主要分布在地缘政治不稳定的地区。目前许多高能锂离子电池仍然在阴极中使用钴氧化物,大多数钠离子电池则通常使用钠锰氧化物、镍氧化物或磷酸盐等不含钴的替代材料,这些原料储量更加丰富且便宜。此外,在低电位下钠离子不与铝形成合金,因此钠离子电池的正负极的集流体均可以使用铝箔。铝箔不仅能降低钠离子电池的成本,还能方便电池充放电到0伏进行储存和运输。综合考虑以上因素,钠离子电池作为锂离子电池替代产品未来可期。

钠离子电池可以使用水系电解质和非水电解质,Namperus LT公司主要研发水系钠离子电池,您选择水系电解质的原因是什么?

我们公司的总体研发方向是水系电池技术,对电荷载体的选择可以是钠、锌、锂或者它们的任意组合。水系电池,顾名思义就是以盐水作为电解液的二次电池,根据最近的研究进展,水系电解质还包括混合电解质,即水和其他溶剂的混合物,以及盐包水电解质,这种新型电解质含有盐、水混合物,盐的浓度高于水。在电池中使用水性电解质有许多优点,例如与常见的有机电解质相比,水性电解质不易燃,具有更高的安全性。其次,它们的离子电导率更高,可以有效提高电池性能,尤其是在电源应用中。并且基于简单盐的水性电解质更便宜,更容易生产和纯化,因此也更容易对这类电池进行维护、处置和回收。

这项电池创新技术有哪些应用场景?

与非水系电池相比,水系电池的主要限制是能量密度较低。在目前的技术发展阶段,这个缺点将它们的应用场景局限在了固定式储能。在固定式储能中,电池的重量和尺寸通常不是首要关注点,安全性和续航能力往往更为重要。也许正因如此,即将出台的法规(例如欧盟电池指令)将进一步提高替代电池技术在一些应用中的地位。

您认为水系钠离子电池达到技术就绪水平需要解决哪些技术难题?研究方向是什么?

在我看来,这个领域需要全面协调发展,包括电极材料或新型电解质的研发、电池部件的二次研发(碳基材料、集流体、超厚电极、干发电极技术等)、全新的电池设计以及电池模组装配。

Namperus LT目前处于哪一阶段?您未来五年的目标和规划是什么?

我们目前主要研发电池材料,材料的选择仍将是新型电池技术研发和应用的主要难题。我们坚信未来 5 到 10 年电池技术将满足不同的应用需求,并在此基础上实现多样化发展。未来我们将在电动汽车中看到的钠离子电池的运用,这种电池无论在材料还是设计方面都将与目前的固定式储能系统中的电池完全不同。我们希望参与进来,贡献我们的力量。

其他相关访谈